In today's rapidly evolving industrial landscape, automation continues to redefine how processes are managed — enabling greater precision, lower energy consumption, and higher uptime. Central to this transformation are motorized control valves: intelligent, automated devices that regulate flow, pressure, and temperature across a wide range of fluid systems. With advancements in smart actuators, connectivity, and control algorithms, motorized control valves are rapidly becoming indispensable components in sectors from oil & gas and power generation to water treatment and chemical processing.

This news article explores the latest developments, market drivers, performance innovations, industry challenges, and real-world applications shaping the motorized control valve landscape in 2026.

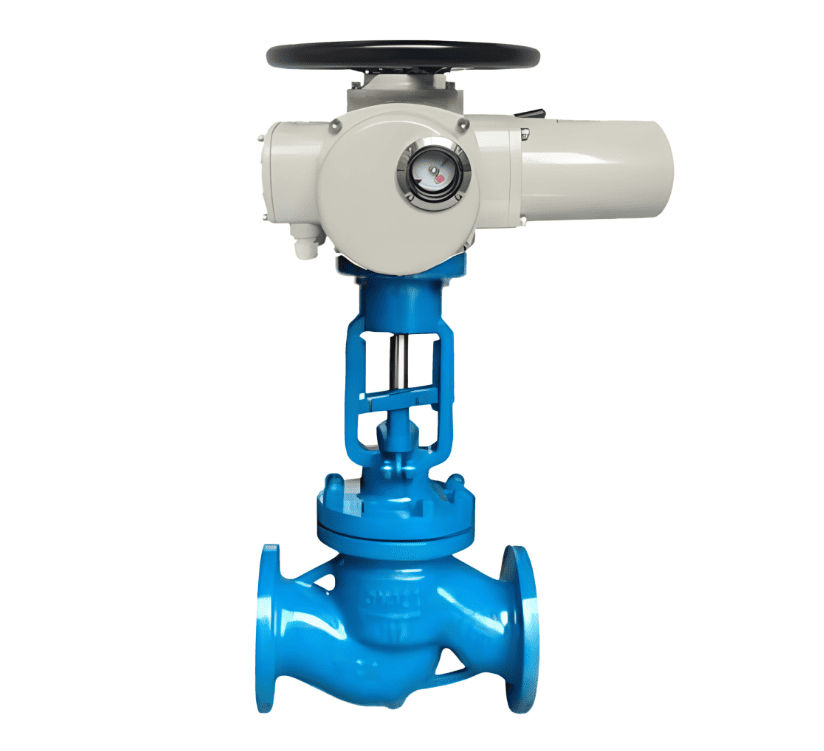

Motorized control valves are automated valves equipped with an electric actuator (motor) that drives the position of the valve plug, ball, butterfly, or other closure element based on a control signal — typically 4–20 mA, digital fieldbus, or other smart protocols.

Unlike manual valves that require human intervention, motorized control valves receive commands from a process controller (PLC, DCS, or PID controller) and modulate fluid flow automatically, enabling:

- Precise regulation of flow, pressure, and temperature

- Remote control and monitoring

- Integration with advanced automation systems

- Improved process efficiency and safety

The motorized actuator converts electrical power into mechanical motion — rotating or linear — to adjust the valve position. Depending on application requirements, these actuators may be simple open/close units or fully proportional devices capable of fine control across the valve's travel range.

The adoption of motorized control valves continues to accelerate globally, driven by several macro trends:

Industries are investing heavily in digital transformation initiatives to achieve real-time monitoring, predictive maintenance, and autonomous process optimization. Motorized control valves with smart actuators and digital communications (e.g., HART, Modbus, Foundation Fieldbus) fit perfectly into this vision — providing actionable data on position, health, torque, and cycle counts.

With edge computing and IIoT platforms, plant operators can now analyze valve performance trends, detect early signs of failure, and optimize control loops — significantly reducing unplanned downtime.

With intensifying regulatory and shareholder pressure to reduce carbon emissions and energy consumption, motorized control valves play a key role in achieving efficient fluid handling. Precisely modulating flow minimizes throttling losses and allows systems to operate closer to optimal operating points.

For example, in HVAC systems, motorized control valves regulate chilled water flow based on real-time demand — reducing pump energy and improving overall system COP (Coefficient of Performance). In oil & gas, accurate pressure control reduces flaring and energy waste.

Many plants built decades ago still rely on pneumatic or manual valves. The ongoing shift toward motorized control solutions — often as retrofit upgrades — offers:

- Higher reliability (no need for compressed air infrastructure)

- Better control stability

- Lower maintenance requirements

- Enhanced diagnostics

Pneumatic systems, once dominant in process control, are gradually being replaced by electric motorized actuators that eliminate costly air compressors and reduce leakage risks.

Modern manufacturing floors and processing plants increasingly adopt digital networks that consolidate sensor, actuator, and controller data. Motorized control valves with native digital connectivity integrate seamlessly into these networks, supporting higher-level analytics and enabling operator dashboards that visualize valve performance across the facility.

This interoperability boosts plantwide visibility and supports centralized optimization strategies.

A typical motorized control valve consists of:

- Valve Body – The mechanical path for fluid; available in globe, butterfly, ball, diaphragm, or other forms depending on application.

- Valve Trim – Internal flow control elements such as plug, cage, seat, or disc that regulate fluid flow.

- Electric Actuator – The motorized drive that positions the valve based on input control signals.

- Positioner / Controller – Device that interprets the control signal and adjusts the actuator to achieve the desired position.

- Feedback Sensor – Provides real-time position and status data back to the control system.

The working cycle generally follows:

- A process controller sends a command (e.g., desired flow rate).

- The motorized actuator receives the signal via the positioner.

- The actuator moves the valve trim to the commanded position.

- The feedback system verifies the actual position.

- Continuous adjustment ensures the process variable tracks the set point.

Thanks to advanced electronics inside modern positioners — including PID control, auto-tuning, and self-diagnostics — many motorized control valves can compensate for nonlinearities and wear over time.

Recent technological breakthroughs are further elevating motorized control valve performance:

Next-generation positioners feature adaptive control algorithms that:

- Auto-tune to plant dynamics

- Compensate for valve hysteresis and friction

- Adjust performance based on fluid properties

These capabilities reduce tuning efforts and improve control loop stability — often yielding faster response and less overshoot.

Modern motorized valves generate diagnostics such as:

- Torque load profiles

- Event logs (stalls, travel limits, reversals)

- Cycle counters

- Ambient temperature and humidity

When integrated with plant asset management software, these insights enable predictive maintenance, reducing unscheduled outages and extending service life.

To facilitate digital integration, many motorized valves support multiple protocols:

- HART – digital overlay on analog signals

- Modbus – for simple digital communication

- Foundation Fieldbus – for fully distributed control

- Ethernet/IP / Profinet – for industrial Ethernet integration

This flexibility lets facilities adopt open networks and future-proof their infrastructure.

New actuator designs emphasize:

- Brushless motors for higher efficiency

- Low-power electronic controls

- Energy recovery features

In remote or power-restricted environments, energy-efficient motorized valves reduce operating costs and support sustainability goals.

Motorized control valves are used wherever fluid control precision matters. Here are major application domains:

In upstream, midstream, and downstream facilities, motorized valves regulate crude, gas, and refined fluid flows. Critical applications include:

- Crude distillation units

- Pressure control in pipelines

- Fuel gas regulation

- Hydraulically actuated systems replaced with electric

High-pressure and high-temperature variants are available to withstand extreme environments.

In thermal and combined cycle power plants, motorized valves play roles in:

- Steam control

- Feedwater regulation

- Cooling water modulation

- Emissions control systems

Precision is paramount: small deviations in steam flow can significantly impact turbine efficiency.

Municipal and industrial water systems use motorized valves to:

- Control distribution pipelines

- Automate treatment processes

- Modulate chemical dosing

Electric actuation eliminates dependence on compressed air, lowering infrastructure costs.

Commercial buildings leverage motorized control valves for:

- Chilled and hot water loops

- Zone temperature control

- Energy-efficient HVAC operations

Integration with building management systems enables optimized comfort and lower utility bills.

These industries require precise control of reactive fluids. Motorized valves help manage:

- Acid/base flows

- Solvent systems

- Batch process control

Tight feedback and advanced position sensing are critical for safety and product quality.

Choosing the ideal valve solution hinges on multiple factors:

Viscosity, temperature, corrosiveness, and particulate content dictate material choices (e.g., stainless steel, alloy, PTFE-lined).

Valve flow characteristic (linear, equal percentage, quick-opening) must match process requirements. Selection affects control loop performance.

Matching actuator power to valve torque requirements ensures reliable operation without overheating or wear.

Outdoor installations may require enclosures rated for rain, dust, or explosive atmospheres (e.g., IP66, NEMA 4X, explosion-proof).

Ensure compatibility with plant control systems and future digital goals.

Despite strong adoption, several challenges remain:

A. Cybersecurity in Connected Environments

As motorized valves join digital networks, they become targets for cyber threats. Manufacturers and operators must prioritize secure communication protocols, firmware protection, and access control.

B. Skill Gaps and Training

Advanced valves require knowledge in digital communications, PID tuning, and diagnostics — skills that are still in short supply in many facilities. Investment in workforce training is critical.

C. Cost Considerations

Compared to pneumatic valves, motorized control valves have higher upfront costs. However, total cost of ownership often favors electric actuation due to lower energy and maintenance expenses — a narrative still requiring broader industry education.

At a major municipal water treatment facility upgrading its distribution network, plant engineers replaced aging pneumatic valves with motorized control valves on key feed lines.

Results included:

- 30% reduction in energy consumption due to elimination of compressed air systems.

- Improved flow stability, reducing pressure surges and water hammer.

- Real-time diagnostics that alerted operators to early wear, preventing unplanned outages.

- This project underscores how motorized control valves not only improve control but also deliver measurable operational savings.

Looking ahead, motorized control valves are positioned at the intersection of intelligent automation and AI-enabled process optimization. Emerging trends include:

Valve manufacturers are embedding digital twin capabilities — virtual replicas of the physical valve and actuator — to simulate performance, optimize settings, and forecast maintenance needs.

Smart controllers with machine learning algorithms can analyze historical behavior, anticipate disturbances, and adjust valve positions proactively — reducing control loop cyclical error.

Cloud platforms aggregate data from thousands of valves across facilities, enabling enterprise-level benchmarking and predictive analytics.

These advancements will further elevate motorized control valves from passive hardware to proactive contributors in automated ecosystems.

Motorized control valves have emerged as essential elements of modern fluid control strategy. Beyond simple actuation, they represent intelligent devices capable of driving performance, reducing energy use, and integrating with digital industrial architectures.

With rapid innovation in smart actuators, diagnostics, connectivity, and AI integration, motorized control valves are set to play an even more strategic role in the industries of tomorrow — from sustainable water management to next-generation manufacturing.

For engineers, plant managers, and automation professionals alike, understanding the capabilities and best practices of motorized control valves is no longer optional — it is a core competency in the journey toward efficient, resilient, and intelligent operations.